| Item No. | Name | Specification | Quantity |

| 1 | LSW-50 induction brazing machine | - | 1 set |

| 2 | induction coil | - | 1 pcs |

| 3 | foot switch | - | 1 pcs |

| 4 | user manual | - | 1 copy |

3. Main Parts of induction heating brazing machine Introduction:

1. Germany INFINEON IGBT Module. 30-100KHZ oscillation frequency,

fast response time, superhigh stability, almost spatter-free

welding )

2. Japan Nichicon electrolytic capacitor. ( filter capacitor )

3. Imported transistor integrated block.

4. All water pipe use thermostability, High pressure resistance

best quality material.

5. Main card, signal circuit, drive circuit board,control circuit

board and components are adopted:Toshiba, Hitachi,Motorola, China's

top manufacturers.

6. International advanced all-solid-state semiconductor power

devices.

7.Technical advantage:perfect control, alarm display circuit,

getting full automatic tracking frequency, continuous adjustable

power, safe dependable protection,clear and accuracy data display

and etc.

8. Superiority Advantages: fast heating, wide application, small

size, easy installation, simple operation, low power consumption,

high efficiency

How Does Induction Heating Work?

When a magnetic field changes near a metal or other conductive

object, a flow of current (known as an eddy current) will be

induced in the material and will generate heat. The heat generated

is proportional to the current squared multiplied by the resistance

of the material. The effects of induction are used in transformers

for converting voltages in all sorts of appliances. Most

transformers have a metallic core and will therefore have eddy

currents induced into them when in use. Transformer designers use

different techniques to prevent this as the heating is just wasted

energy. In this project we will directly make use of this heating

effect and try to maximise the heating effect produced by the eddy

currents.

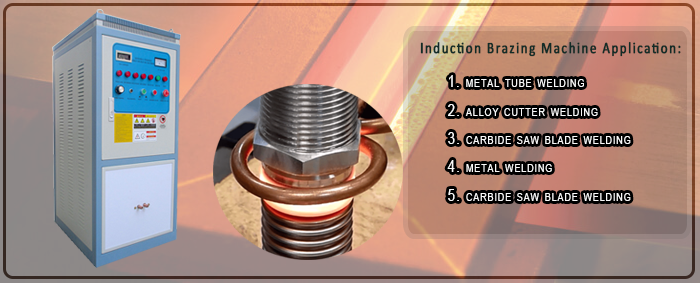

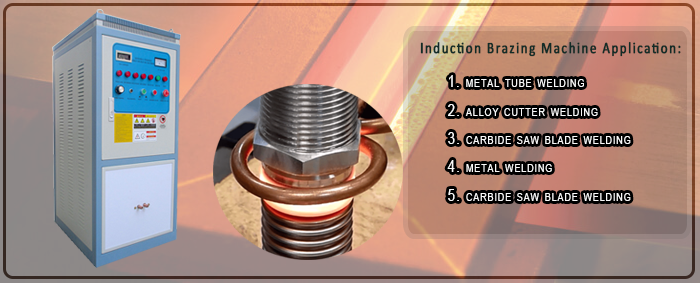

Induction Heating Machine Application:

Forging(Bar,flat plate,bar end heating,pipe ends,bar end heating)

Pre-heating(Pipe,steel wire,stainless steel wire)

Brazing(Saw blades,carbide tools,cooper tube,aluminum part,drilling

tools,Pan)

Annealing(Steel pipe,golf ball head,brass lock,aluminum pan)

Hardening(Gear,shaft,pipe,bearing,pump fitting,steel plate,roller)

shrink fitting(motor,pipe)