Auto Parts High Frequency Sprocket Induction Hardening Quenching

Equipment

1. Application of Induction Hardening Machine :

1. Heat treatment of various hardware tools and hand tools. Such as

pliers, wrenches, screwdrivers, hammers, axes, etc.

2. High-frequency quenching treatment of various auto parts and

motorcycle parts. Such as: crankshaft, connecting rod, piston pin,

crank pin, sprocket, camshaft, valve, various rocker arms, rocker

arm shafts; various gears in the gearbox, spline shafts,

transmission half shafts, various small shafts , All kinds of forks

and other high-frequency quenching treatment.

3. High-frequency quenching treatment of gears, shafts, etc. on

various power tools.

4. Heat treatment for high frequency quenching of various hydraulic

components and pneumatic components. Such as the column of a

plunger pump.

5. Quenching treatment of plugs, rotors of rotor pumps; reversing

shafts on various valves, gears of gear pumps, etc.

6. Heat treatment of metal parts. Such as high-frequency quenching

treatment of various gears, sprockets, various shafts, spline

shafts, pins, etc.

7. Quenching treatment of machine tool bed guide rails in the

machine tool industry.

2.Technical advantage of high frequency quenching machine:

perfect control, alarm display circuit, getting full automatic

tracking frequency, continuous adjustable power, safe dependable

protection,clear and accuracy data display and etc.

Superiority Advantages: fast heating, wide application, small size,

easy installation, simple operation, low power consumption, high

efficiency.

Heat treatment process is the metal work-pieces heated to a certain

temperature, obtained different matrix organization after different

ways of cooling, so that to achieve the required mechanical

properties (material harder or softer), such as quenching,

annealing, etc.

2. Technical Parameter of High Frequency Induction Hardening

Quenching Equipment:

Working voltage | 380V/50HZ |

Voltage range | 340V-420V |

DC power | 300KW |

DC current | 480A |

Oscillation frequency | 10-20KHZ |

Efficiency | 90% |

Duty cycle | 100% |

Weight | 380KG |

Dimension | 1070*640*1870mm,1020*530*690mm |

Cooling water flow | 0.2MPa-70L/Min,0.2MPa-80L/Min |

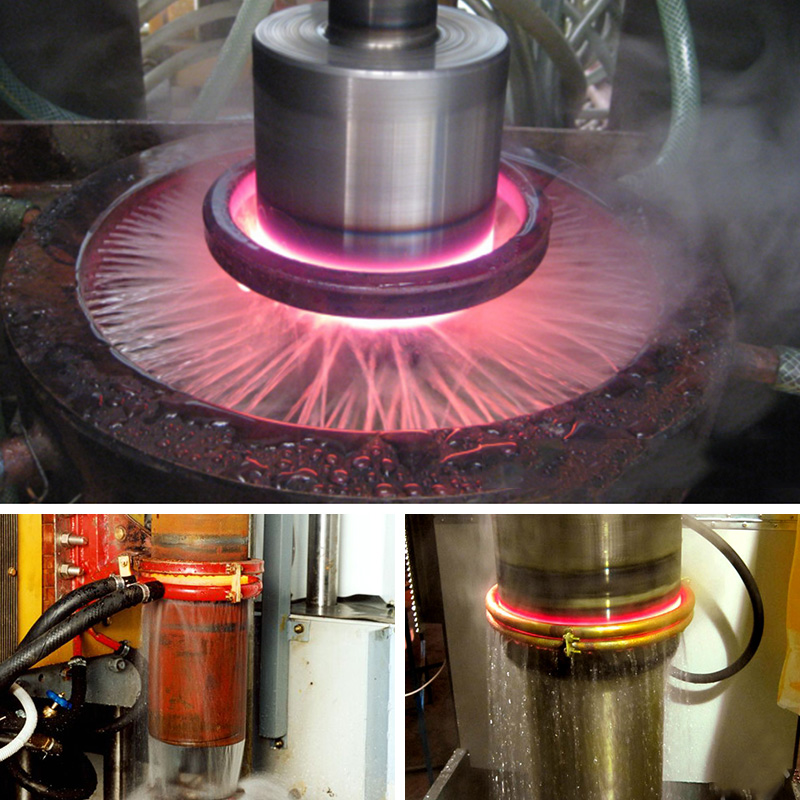

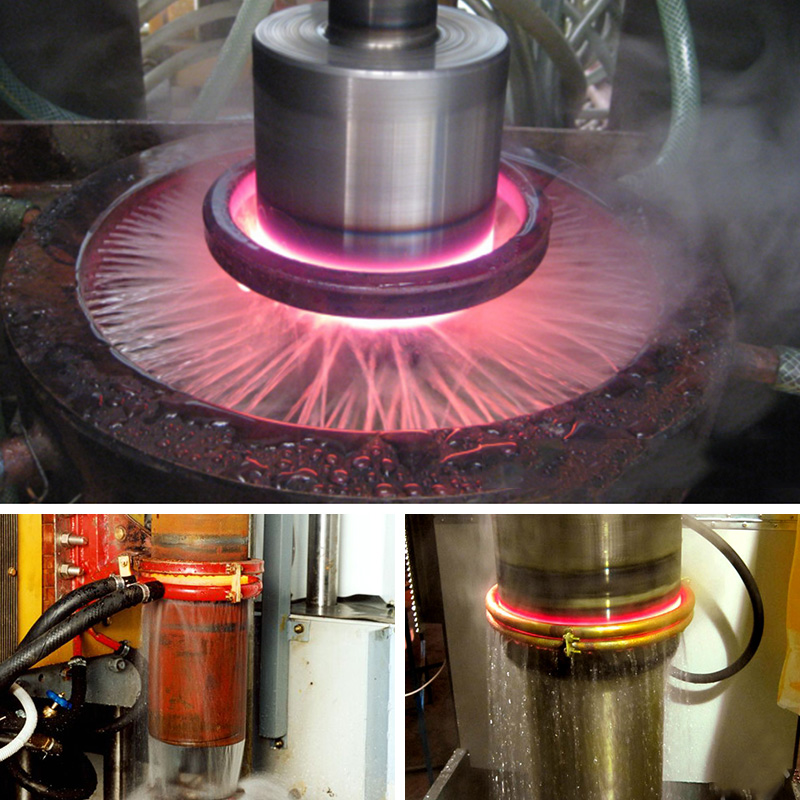

3. Induction Quenching Hardening Equipment Application Cases:

4. Avantage of high frequency induction quenching equipment

1. Easy to use, simple to operate, and can be opened or stopped at

any time. And do not need to warm up.

2. Manual operation, semi-automatic and full-automatic operation;

Can be a long time to continue to work, can also be used that is to

stop random use. It is beneficial to the use of the equipment in

the low electricity price preferential period.

3. High energy utilization rate, environmental protection and

energy saving, safe and reliable.

Germany INFINEON IGBT Module. ( 40-60KHZ oscillation frequency,

fast response time, superhigh stability, almost spatter-free

welding )

Japan Nichicon electrolytic capacitor. ( filter capacitor )

Imported transistor integrated block.

All water pipe use thermostability, High pressure resistance best

quality material.

Main card, signal circuit, drive circuit board,control circuit

board and components are adopted:Toshiba, Hitachi,Motorola, China's

top manufacturers.

International advanced all-solid-state semiconductor power devices.

1. It adopts the IGBT inverter circuit in parallel connection,

which has high load adaptability.

2. The comprehensive full load design is available for 24-hour

continuous operation.

3. The digital phase locked realizes following frequency

automatically.

Design in modules. It is installed facility and use conveniently

without debugging..

4. The perfect protection function, insuring the reliability and

easily maintaining of the equipments.

5. The technique of converting frequency by resonance promotes

efficiency of whole equipment by over 95%.

6. Economy and environment protection, it can replace of

gas/coal/electronic tube induction heating machine.