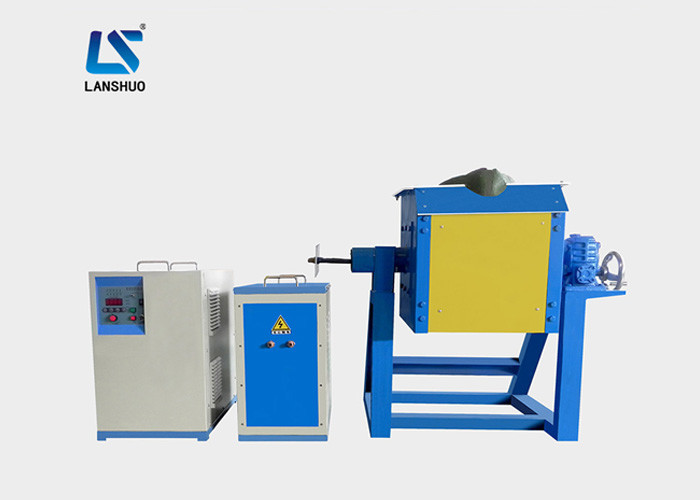

LSW-120 120kw Steel Bar Industrial high frequency Induction Heating

Equipment for forging

1. Advantages of high frequency induction heating equipment:

Fasteners are indispensable general-purpose parts for machinery,

metallurgy, electrical appliances, instrumentation, petrochemicals,

agricultural machinery, mining, construction, transportation,

weapons and aerospace industrial equipment and tools, and are used

as fastening connections. It mainly includes threaded fasteners,

washers, pins and rivets. With the advancement of science and

technology and the development of industrial technology, new

materials and structures, as well as new fasteners processed by new

technology methods have come out one after another, and the

performance requirements are getting higher and higher. Therefore,

the role of heat treatment to ensure the inherent quality and

excellent performance of fasteners is more and more important. The

equipment for heat treatment of fasteners is commonly used in the

medium frequency heating power supply.

The advanced solid-state inverter control technology adopted by the

intermediate frequency heating power supply has stable performance

and high heating efficiency. In a short time, the heating speed is

fast, which reduces the oxidation area of the fasteners, reduces

the probability of deformation of the fasteners, and the heating is

uniform, and each part of the fasteners will be heated, which is

very convenient. The fasteners are not easy to deform and break,

which enhances its toughness and hardness, and the pressure

resistance has also undergone great changes. The pass rate is very

high, and the effect is better than expected. In the application,

the fasteners can play a better role its role.

2. Technical Parameters of LSW-120 IGBT induction heating machine:

| Model | LSW-120 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 120kw |

| Oscillation frequency | 18-35KHZ |

| Duty cycle | 100% |

| Cooling water flow | 45L/Min,0.2MPa |

| Weight | 230kg |

| Dimension (L*W*H ) | 600*480*1360mm / 800*500*580mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating,quenching etc |

3. Applications of IGBT induction heating machine:

1. Heating: mainly for carbon steel, stainless steel, alloy, brass, aluminum

etc heating.

2. Forging: whole and partial induction forging for metal bar.

3. Work piece hot forging and rolling: standard parts, fasteners, automobile parts, small hardware, round

bar and billet, etc.

4. Specific application for the induction forging heater:

(1) bolts and nuts forging and hot upsetting

(2) pipe induction forging and forming

(3) auto parts (connecting rod, crank shaft, etc.), cast iron beam

heating and continuous heating

(4) oxygen bottle forging

(5) rivet heating

(6) long / round / square / angle bar and billet heating, etc.

4. Main Features of IGBT induction heating machine: