220V IGBT Copper Workpiece high frequency induction heating brazing

equipment

1. Induction Brazing Machine Brief Introduction :

high frequency induction heating equipment is particularly suitable

for heat treatment and quenching, melting, annealing, the metal

through the heat forging, extrusion, welding, brazing.

1. For welding the diamond segments ,grinding wheel;

2. Environment friendly design , voltage instability;

3. The machine can be automatic temperature control to realize with

equipment;

4. High power ,High heating Speed, widely application range that

can use various diamond tools;

5. Imported key parts ,lowest hitch, Small in size and taken

easily.

2. Technical Parameters of LSW-16 Induction Heating Machine:

| Model | LSW-16 |

| Working Voltage | 220V, 50/60HZ |

| Max input power | 16kw |

| Oscillation frequency | 28-40KHZ |

| Duty cycle | 100% |

| Cooling water flow | 20L/Min,0.15-0.2MPa |

| Weight | 25kg |

| Dimension (L*W*H ) | 420*200*360mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating, brazing,melting etc |

3. Main characteristics of LSW-16 Induction Brazing Machine :

1. Adoping MOSFGT and IGBT inverting device, tracking frequency

automatically

2. High frequency, heated quickly, its powei consumption is only

20%~30% of eletronic tube induction heating machine and other

heating style.

3. Security and reliability, the equipments have the secure voltage

and it's secure to operate

4. Manual, automatic regulating automatically, it can protect

itself from over voltage, over current, lack of water, phase fail,

over hot, etc

5. Recommend usage: Weld, forging, hot cooperate, melting,

quenching, anneat etc.

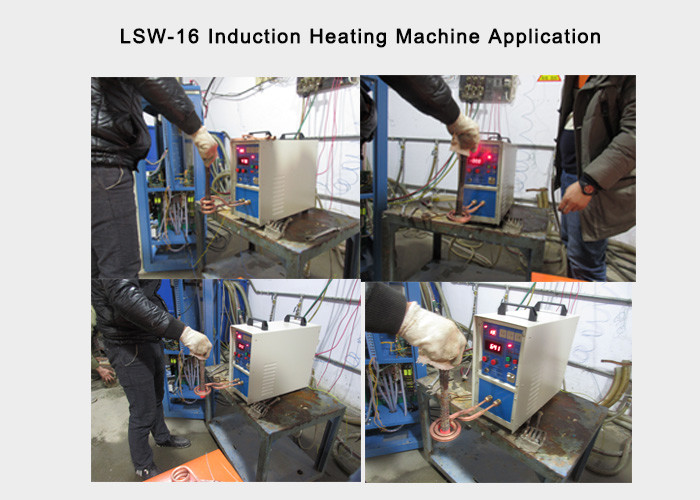

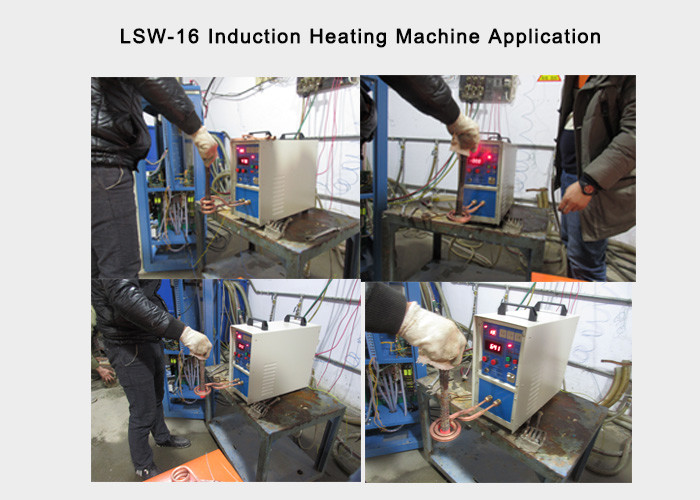

4. Induction Brazing Machine Application:

Heat treatment industry

1. a variety of steam, Motorcycle high-frequency hardening heat

treatment, such as: crankshaft, connecting rod, piston pin,

camshaft, valves, various gears within the gearbox, a variety of

fork, all kinds of spline shaft, drive axle, various small shaft

crank pin, a variety of rocker, rocker shaft, high-frequency

hardening heat treatment.

2. the hardware high-frequency hardening heat treatment, such as

pliers, hammers, strong pliers, wrenches.

3. hydraulic components such as: piston pump plunger, rotor pump

rotor, conversion shaft of the valves, gear of gear pump high

frequency quenching.

4. various electric tools gear shaft of the high-frequency

hardening heat treatment.

5, a variety of carpentry tools, such as: axes, planing and other

heat treatment.

Forging industry

1. plate heating, bending and forming.

2. standard parts, fasteners through the hot forming.

3. the hardware tools through heat, such as pliers, wrenches and

other heat through hot forming.

4. taper shank drill rod extrusion prospecting.

5. the pipe through the hot forming, such as bends and so on.

Brazing

1. metal tube welding: such as copper tube, steel tube, and

aluminum tube’s butt welding, plug welding and welding sets.

2. alloy cutter welding: such as alloy turning, milling cutter,

planer, saw blades, reamer, boring knife.

3. carbide saw blade welding: diamond saw blade welding, marble saw

blade welding,woodworking saw blade welding, cut grass piece of

welding, cut aluminum welding,

4. metal welding:such as: towel rack, soap nets, towel holder,

auto-accessories,motor accessories, metal terminals, hardware

pieces, electric heating tube parts and fasteners.

Smelting

Steel,iron, non-ferrous metals,graphite crucible smelting