LSW-16 16kw IGBT electric high frequency Induction copper brazing

machine

1. Induction Brazing Machine Brief Introduction :

Induction brazing is a process in which two or more materials are

joined together by a filler metal that has a lower melting point

than the base materials using induction heating.Brazing is a

materials joining process that uses a filler metal (and usually an

anti-oxidizing solvent called flux) to join two pieces of

close-fitting metal together without melting the base materials.

Instead, induced heat melts the filler, which is then drawn into

the base materials by capillary action.

high frequency induction heating equipment is particularly suitable

for heat treatment and quenching, melting, annealing, the metal

through the heat forging, extrusion, welding, brazing.

2. Technical Parameters of LSW-16 Induction Heating Machine:

| Model | LSW-16 |

| Working Voltage | 220V, 50/60HZ |

| Max input power | 16kw |

| Oscillation frequency | 28-40KHZ |

| Duty cycle | 100% |

| Cooling water flow | 20L/Min,0.15-0.2MPa |

| Weight | 25kg |

| Dimension (L*W*H ) | 420*200*360mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating, brazing,melting etc |

3. Main characteristics of LSW-16 Induction Brazing Machine :

Induction brazing can join a wide range of metals, even ferrous to

non-ferrous. Induction brazing is precise and quick. Only narrowly

defined areas are heated, leaving adjacent areas and materials

unaffected. Correctly brazed joints are strong, leak-proof and

corrosion resistant. They are also very neat, usually requiring no

further milling, grinding or finishing. Induction brazing is ideal

for integrating into production lines.

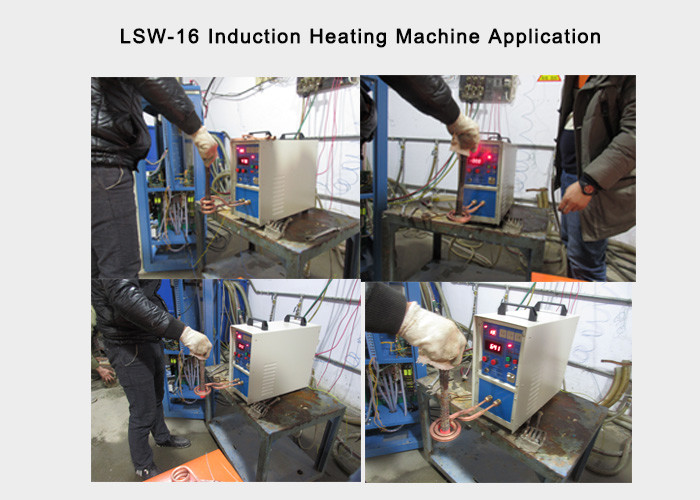

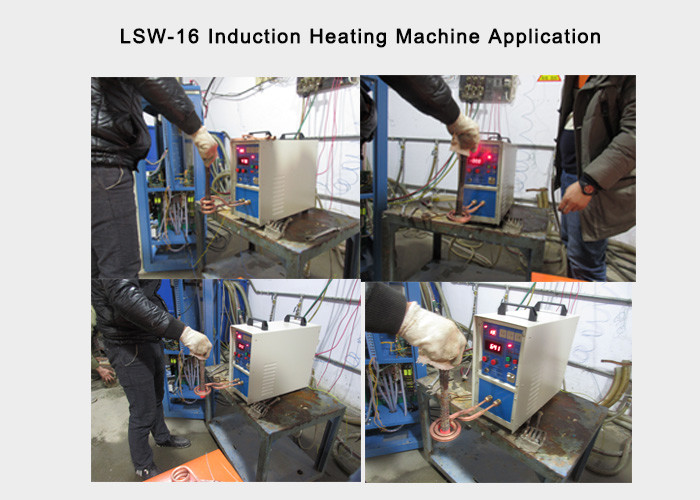

4. Induction Brazing Machine Application:

Heat treatment industry

1. a variety of steam, Motorcycle high-frequency hardening heat

treatment, such as: crankshaft, connecting rod, piston pin,

camshaft, valves, various gears within the gearbox, a variety of

fork, all kinds of spline shaft, drive axle, various small shaft

crank pin, a variety of rocker, rocker shaft, high-frequency

hardening heat treatment.

2. the hardware high-frequency hardening heat treatment, such as

pliers, hammers, strong pliers, wrenches.

3. hydraulic components such as: piston pump plunger, rotor pump

rotor, conversion shaft of the valves, gear of gear pump high

frequency quenching.

4. various electric tools gear shaft of the high-frequency

hardening heat treatment.

5, a variety of carpentry tools, such as: axes, planing and other

heat treatment.

Forging industry

1. plate heating, bending and forming.

2. standard parts, fasteners through the hot forming.

3. the hardware tools through heat, such as pliers, wrenches and

other heat through hot forming.

4. taper shank drill rod extrusion prospecting.

5. the pipe through the hot forming, such as bends and so on.

Brazing

1. carbide cutting tools welding. Such as turning, milling, cutter

knife.

2. the diamond saw blade welding. Such as diamond saw blade,

abrasive, jagged welding. Exploration drill bit used in welding,

such as word drill, drill welding horns.

3. brass, copper

Smelting

Steel,iron, non-ferrous metals,graphite crucible smelting