LSW-200 200kw Industrial Steel Bar high frequency induction

hardening quenching machine equipment

1. Brief Introduction of Induction Quenching Hardening Machine :

1. Various auto parts motorcycle accessories, high-frequency

quenching heat treatment, such as: crankshaft, connecting rod,

piston pin, camshaft, valve, various gears in the gearbox, various

forks, various spline shafts, transmission shafts , Various small

shaft crank pins, various rocker arms, rocker shafts and other high

frequency quenching heat treatment.

2, hardware tools high-frequency quenching heat treatment, such as

vise, hammer, pliers, wrenches.

3. Hydraulic components such as plungers of plunger pumps, rotors

of rotor pumps, reversing shafts on various valves, gears of gear

pumps, etc.

4. High-frequency quenching heat treatment of various power tool

gear shafts.

5, a variety of woodworking tools, such as: axe, planer and other

heat treatment.

2. Technical Parameter of High Frequency Induction Hardening

Quenching Machine:

Working voltage | 380V/50HZ |

Voltage range | 340V-420V |

DC power | 200KW |

DC current | 320A |

Oscillation frequency | 10-20KHZ |

Efficiency | 90% |

Duty cycle | 100% |

Weight | 380KG |

Dimension | 1070*640*1870mm,870*530*600mm |

Cooling water flow | 0.2MPa-50L/Min,0.2MPa-60L/Min |

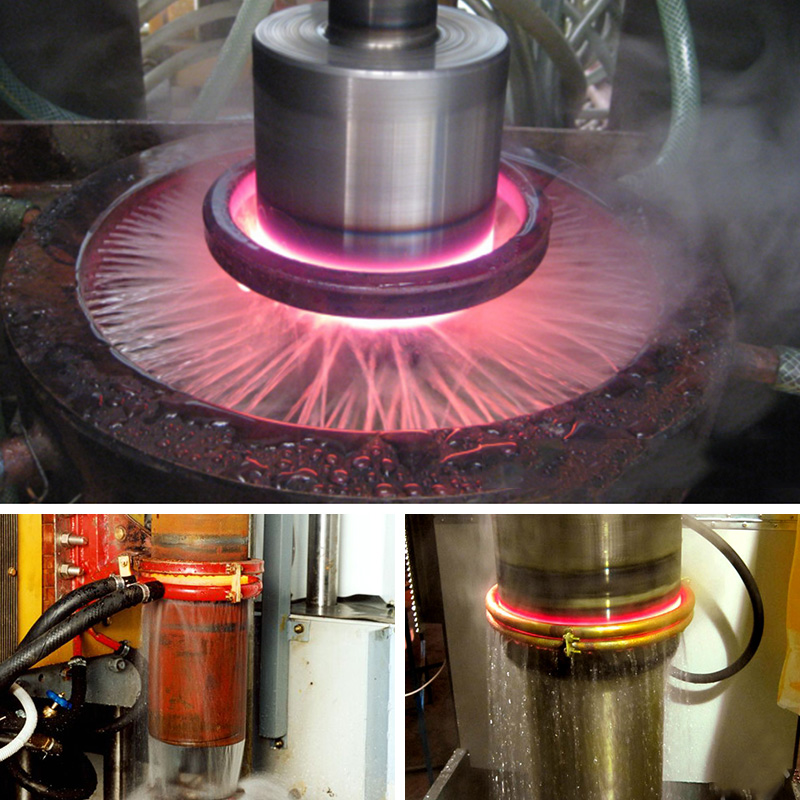

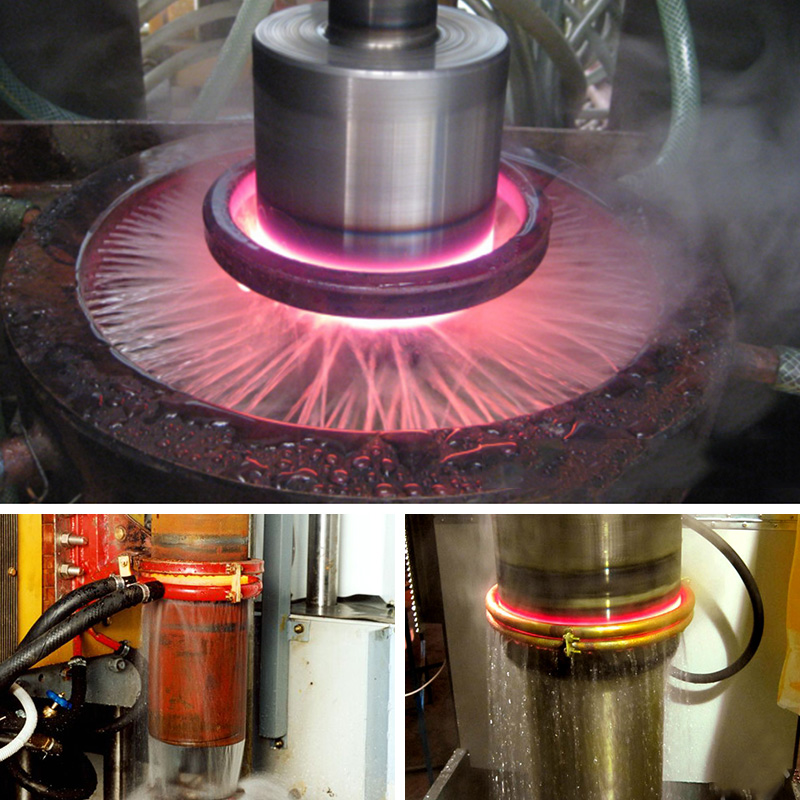

3. Induction Quenching Hardening Machine Application:

(1) For auto parts and motorcycle parts hardening.

(2) For machinery parts, like gears, transmission wheels, axles,

shafts, spline shafts, ball stud hardening.

(3) For machine tools quenching, like guide rail machine tools

hardening.

(4) For spanner, pliers, CNC machines, hammer, axe hardening etc.

4. Main Feature of high frequency induction quenching machine:

It adopts the IGBT inverter circuit in parallel connection, which

has high load adaptability.

The comprehensive full load design is available for 24-hour

continuous operation.

The digital phase locked realizes following frequency

automatically.

Design in modules. It is installed facility and use conveniently

without debugging..

The perfect protection function, insuring the reliability and

easily maintaining of the equipments.

The technique of converting frequency by resonance promotes

efficiency of whole equipment by over 95%.

Economy and environment protection, it can replace of

gas/coal/electronic tube induction heating machine.

1. Full protection functions such as over current, over voltage,

voltage limiting, current limiting, over frequency, temperature

protections etc..

2. The power supply is PLC controlled which can be connected to the

quenching lathe.

3. The quenching lathe is compact and adopts standard structual

steel type.

4. Various quenching type: continuous scanning quenching, timing

quenching, segment scanning etc.

5. This machine is adapted to automatic work which is of high

production effect, low operation cost. The control system adopts

PLC which can control all data.

6. The control system can monitor the quenching speed, heating

power, quenching liquid pressure as well as cooling flow.

7. All the quenching parameters can be stored and invoked up as

customer's will.